"Responsible Gold?"

There is a lot of current press regarding what is known as "Responsible Gold." This is a term coined to describe ecologically friendly mining techniques. The truth of the matter is that precious metal mining has historically been destructive to the enviornment. One only has to travel to the former gold fields in California to see the still denuded cliffs which were blasted with streams of water in order to remove gold bearing rock. 70% of the gold mined in the world goes into the fabrication of finished jewelry.

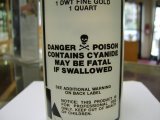

There is a lot of current press regarding what is known as "Responsible Gold." This is a term coined to describe ecologically friendly mining techniques. The truth of the matter is that precious metal mining has historically been destructive to the enviornment. One only has to travel to the former gold fields in California to see the still denuded cliffs which were blasted with streams of water in order to remove gold bearing rock. 70% of the gold mined in the world goes into the fabrication of finished jewelry.Nevada is currently the leading producer of gold in the USA. The primary occurence is called the Carlin Trend. It is located west of the city of Elko in Northern Nevada. Dangerous elements such as Mercury, Arsenic, and CYANIDE are used to extract microscopic gold from the earth. The days of finding large nuggets or "easy pickings," are long gone.With the current spot price of gold at over $600.00\ounce previously uneconomical deposits are being reworked. While metallurgical engineering may provide ecologically friendly technology for mining someday, it has not done so yet. None of us want to see what is left of the earth destroyed in the pursuit of greedy corporate profits. WAIT! The shareholders in these multi-national mining corporations are in the way! Not to worry. The enviornmentalists have already won their case in the court of public opinion.